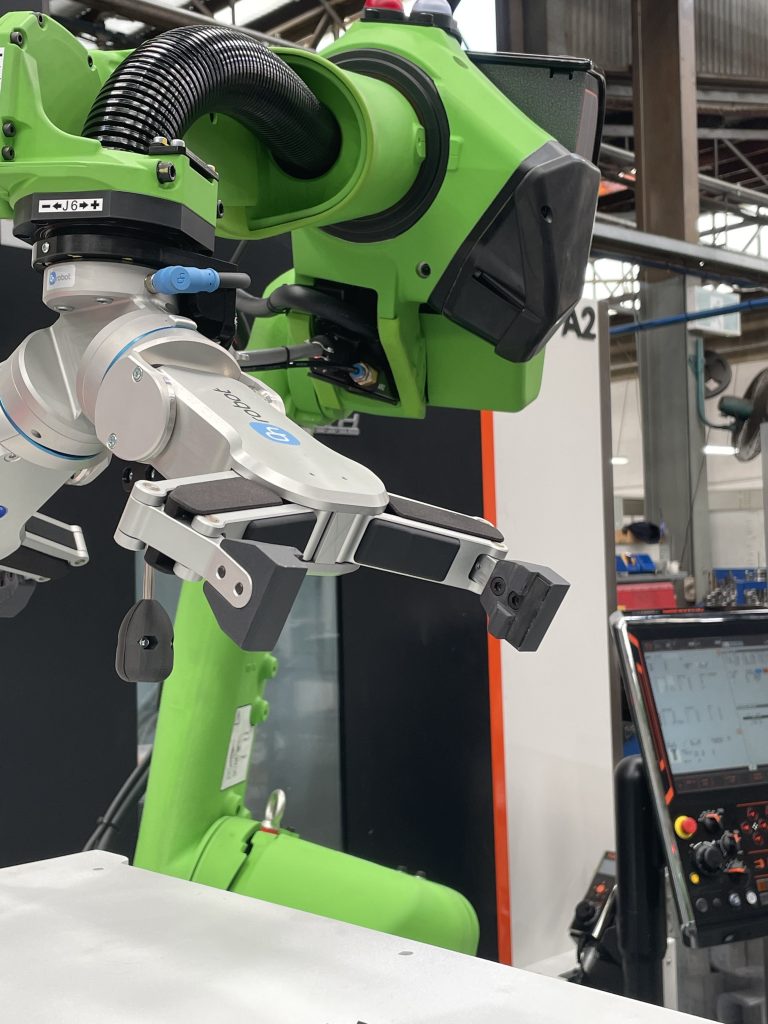

Oilpath’s CNC machines

At Oilpath, we endeavour to manufacture hydraulic products that offer reliability, performance, and longevity. We use state-of-the-art Mazak CNC machining centres to create our custom manifolds to ensure the products you receive are of the highest standards without compromise. With our range of advanced CNC facilities, we can efficiently manufacture complex hydraulic components with the utmost precision.

Oilpath is a hydraulic systems designer and manufacturer, not a machine shop, so we have vast experience and understanding of the importance of internal and interface surface finish. Every component and manifold block goes through a thorough deburring process to minimise risks during operation and enhance the operational efficiency of your hydraulic system.

Our hydraulic test bench facilities with burst testing capabilities ensure all hydraulic products are rigorously tested before leaving the factory.